PVC PIPELINE SYSTEMS

‘PVC’ is an acronym used for Polyvinyl Chloride. It is the third-most extensively utilised synthetic polymer. It is manufactured and employed at the rate of 40 million tons a year globally. Its main application is to be used as a channel for water in several contexts.

Now, what is it composed of?

What makes it a product in demand?

The source material used in it is polyvinyl chloride. Owing to its number of valuable physical and chemical properties, it is the paragon choice for a safe and cost-effective conduit in a wide range of infrastructure applications. Among those applications, water supply happens to be the principal one.

AnZ waters is the leading supplier of PVC pipes and fittings. We have acquired an honourable position among the great dealers of PVC products. An experience of around 20 long years has made AnZ Waters, efficient vendors in the wide spectrum of PVC pipes and fittings.

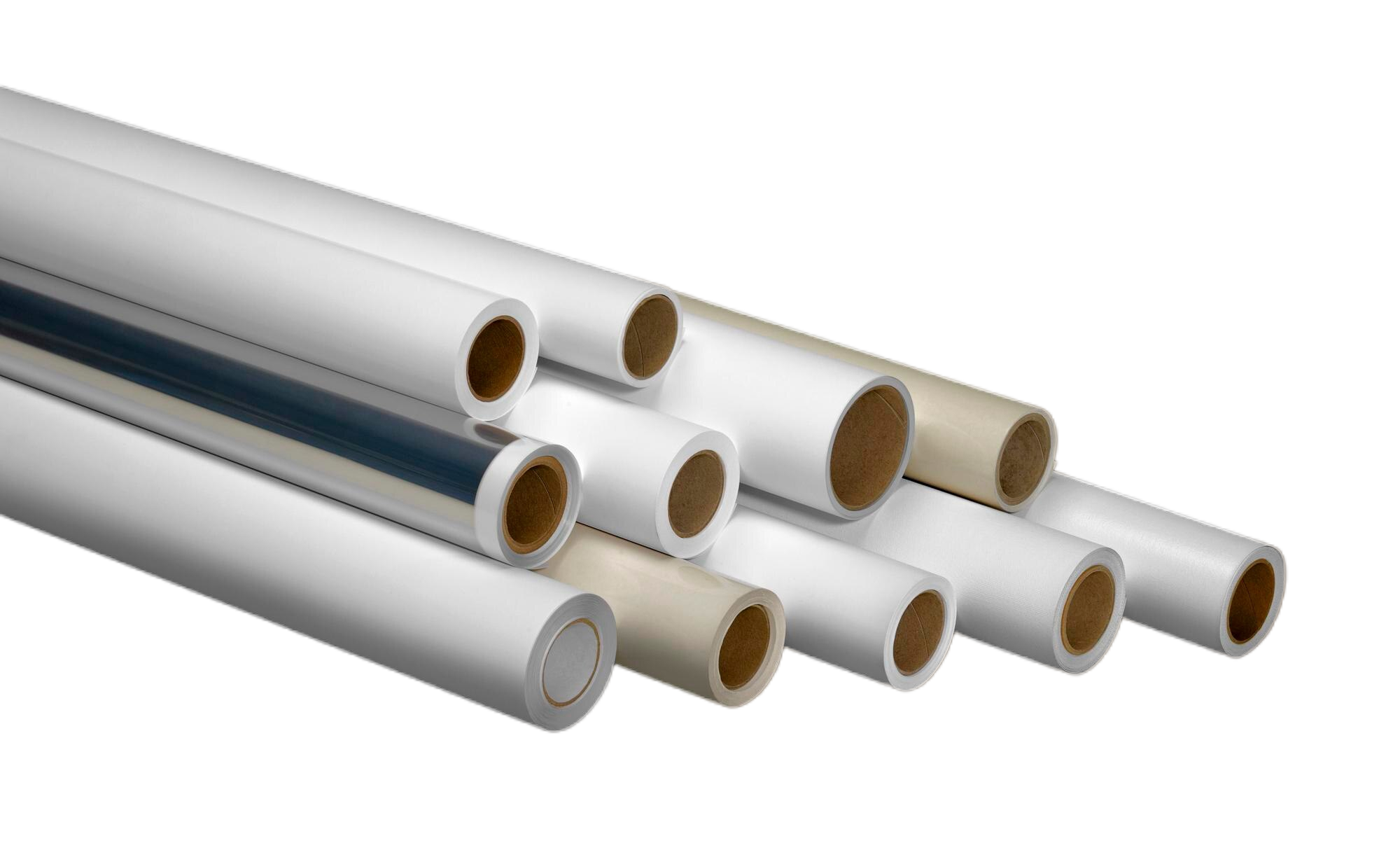

What are PVC pipes?

PVC is an abbreviated name for polyvinyl chloride. It is nothing but a chlorinated hydrocarbon polymer. Talking about its natural state, it is rigid and brittle. But , it becomes more resilient and malleable, when it gets blended with additions such as plasticizers.

Some of its applications, usually include electrical insulation, medical tubing, flooring, furniture, signage. It is also employed as a substitute for rubber. But its most extensive use is in the manufacture of pipes. Now, these pipes are basically used in water supply, plumbing as well as irrigation.

Subject to the application, a handful of variants of PVC pipes are utilized as hot or cold water ducts in not only industrial but also commercial contexts. PVC pipes have been used for over 80 years for several commercial purposes. Considering the United States alone, 2 million miles of PVC pipelines are operative at present.

What are PVC pipes and fittings used for?

- PVC pipes and fittings are pervasive in the background of water supply. The pipelines used for water mains almost completely comprises of PVC pipes. Moreover, sanitation sewer networks and large-scale irrigation networks also consist of PVC pipes.

- In the residential and commercial fields, PVC pipes and fittings are used in plumbing, drainage, agricultural irrigation, electricity & telecommunications systems. Also they are extensively utilized in the ductwork of heating and cooling systems.

- Underground PVC pipes and fittings possess a larger bore along with a thicker wall, which are utilised by utility companies in order to provide drinking water through a network to not only the residential buildings but also the commercial ones.

- An underground PVC pipe network is of great use for sewage systems. They are employed for rainwater drainage from roofs as well as other structures. In addition to that, they are also used to construct sprinkler systems for landscaping along with fire sprinkler systems in buildings.

- The hot water in HVAC (Heating, Ventilation and Cooling) systems are conveyed through pipes made of CPVC, which is a variant of PVC. However, cold water in HVAC systems is transported through PVC pipes.

- PVC water supply pipes are also used for the purpose of agricultural irrigation. It normally saves 30-50% water if you compare it with the open channel systems. Along with this, It can also prevent the incidence of soil salinization, swamping and cold flooding. Owing to the fact that majority of the PVC water pipe network is buried underground, the rate of land utilization is high.

- The PVC pipeline water delivery system is really flexible along with being convenient. In addition to that, it is easy to

adjust and realize automation. It proves to be a suitable and reliable choice for different terrains and soils. Furthermore, the speed of water delivery is fast and the irrigation efficiency happens to be quite high. All of these factors make the maintenance, an easy job.

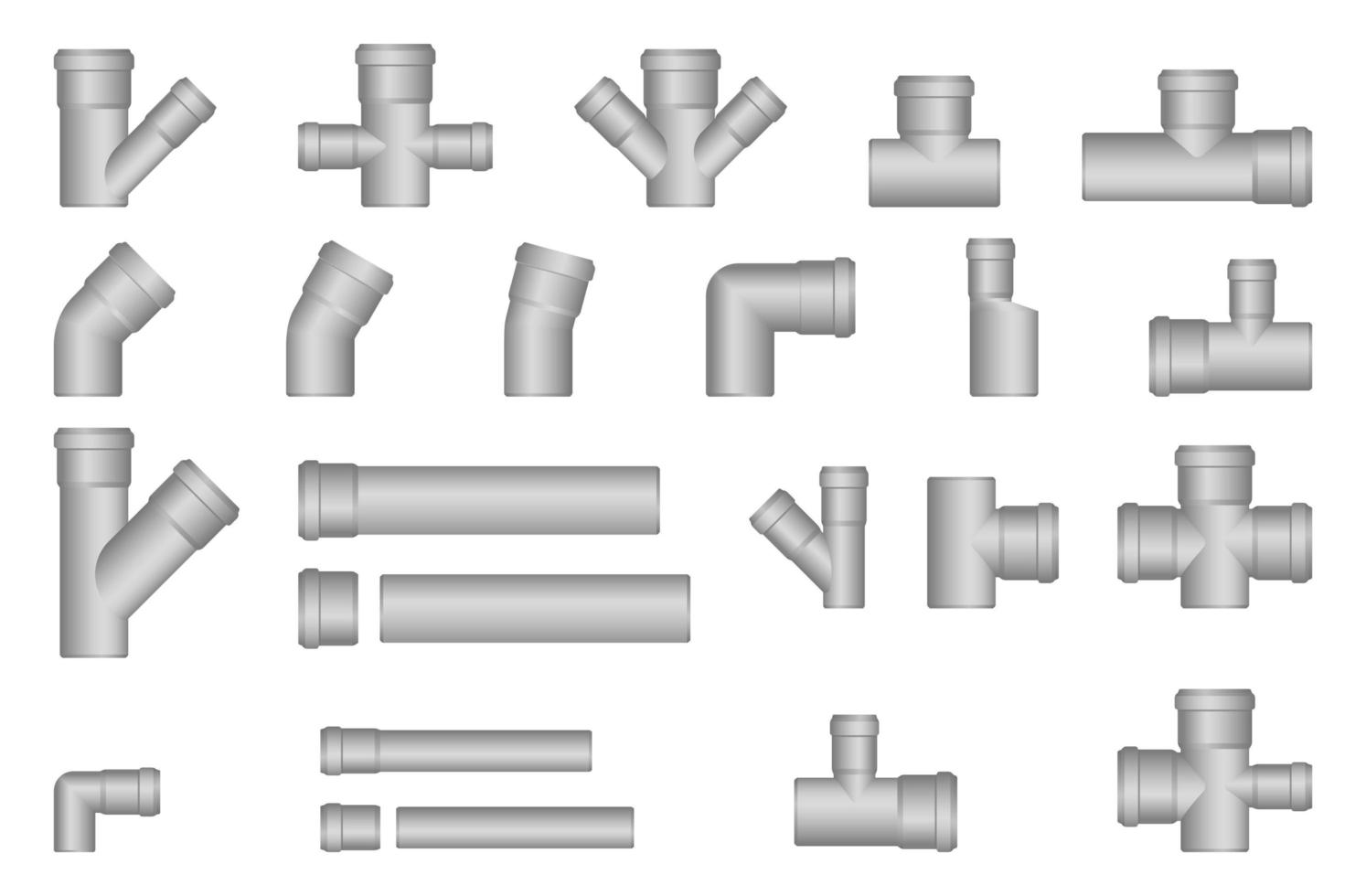

- PVC pipe fittings such as bends, branches, valves, brackets and clips can be employed in a broad spectrum of pipelines and construction. They can be efficiently used to bring up to date older pipeline systems which could be wearing out with age. The shortcoming of pipeline networks lies chiefly in the integrity of their joints. PVC pipes and fittings can be utilized to enhance the junction points, as a result of which the entire network will not be needed to be restored.

What are the benefits of PVC pipes?

- PVC pipes are the reliable media to transport water and electricity in a number of sectors. Their high resistance to heat and corrosion contribute a great deal to their expansive utilization.

- As a result of its smooth surface, there is a low level of friction between PVC and flowing liquids when you compare it with concrete or metal. This makes it an excellent material for pipes that serve as channels for water supply.

- It is lightweight whose transportation is quite easy over large distances to be laid as pipelines. This can be simplified as- less fuel is consumed in order to transport them, which makes them eco-friendly.

- It is cost-effective owing to the fact that a relatively simple process is used for its mass production.

- It is quite easy to mold into different shapes, which makes it a versatile material with a broad spectrum of applications.

- It reveals good strength and high durability. It also possesses high resistance to large amounts of stress. This makes it a great choice of material for underground pipes and pipes through which pressurized fluids are required to be conveyed.

- A beneficial chemical property of PVC, definitely, is its inertness or resistance to chemical reactions with other substances. Because of this, it becomes safe for the transportation of potable drinking water and water that is utilised for household purposes.

- PVC can last a thousand years when installed underground. This makes it low-maintenance and a favourable material for massive pipeline networks, whose maintenance as well as repair costs would be exceedingly high with legacy raw materials such as steel, iron and cement.

- The installation of PVC pipes is very easy. Also, they are not only easy to dismantle but also maintain. Its failure or break rate is exceptionally low when you compare it with the legacy materials.

- The low amount of carbon in PVC is the cause for less harmful emissions at the time of its production. They can be easily recycled as well as reused for other purposes, either from the salvage and re-purposing of construction waste or recycling of industrial waste. Around eight thousand tons of PVC is recycled each year in Europe.

The Different Types Of PVC Plastics

Depending upon the amount of plasticizer content, PVC plastics are basically divided into two major types: One being rigid PVC while the other is flexible PVC.

Among them, flexible PVC captures a third of the market. On the other hand, rigid PVC accounts for two-thirds of the market.

- Rigid PVC

Rigid PVC relates to PVC plastics that consist of no or very little plasticizer (less than 10%), while those without any plasticizer are referred to as PVC-U.

Rigid polyvinyl chloride possesses good mechanical strength, superb weather resistance, and excellent flame resistance. In addition to that, it can be used alone as a structural material.

It is employed in the chemical industry for the purpose of manufacturing pipes, sheets, and injection-molded products.

- Flexible PVC

Flexible PVC is the product of the addition of 30-70% plasticizer to PVC resin along with a particular amount of stabilizers along with other additives.

Flexible PVC is distinguished by its flexibility as well as transparency, revealing good elasticity and great cold resistance.

However, when comparing it with rigid PVC, it possesses lower strength, is quite prone to brittleness, and fails to preserve very well over long periods.

Common uses of flexible PVC cover production of flooring, ceilings, as well as leather surfaces.

In addition to these two types of PVC materials, Chlorinated PVC (CPVC), PVC-O, and PVC-M are also moderately common types.

- Chlorinated PVC (CPVC)

Chlorinated PVC, also termed as CPVC, is a result of further chlorination of PVC resin, with the resultant CPVC resin possessing a chlorine mass fraction of 65% to 72%.

The increased chlorine content substantially improves the material’s heat resistance, aging resistance, corrosion resistance. It also greatly improves its chemical stability.

- PVC-M (Modified Polyvinyl Chloride)

PVC-M is upgraded in impact resistance due to the addition of specific modifiers, such as acrylic along with styrene-butadiene rubber.

- PVC-O

PVC-O, also called as Biaxially Oriented Polyvinyl Chloride, undergoes axial stretching or radial stretching in order to align its molecular chains even more orderly, as a result, significantly enhancing not only the strength but also pressure resistance of the material.

Types of PVC pipes and fittings

AnZ waters have a wide range of PVC pipes, fittings and valves that are listed below

- PVC pipes sch 80

- PVC coupling sch 80

- PVC TEE sch 80

- PVC elbow sch 80

- PVC reducer sch 80

- PVC y-strainer

- PVC male adapter sch 80

- PVC female adapter sch 80

- PVC threaded fittings sch 80

- PVC valve

- PVC ball valve

- PVC diaphragm valve

- PVC primer

- PVC glue