PPH PIPELINE SYSTEMS

PP (Polypropylene) is a thermoplastic polymer which is synthesized from propylene. It possesses good electrical insulation, excellent chemical corrosion resistance along with quite good heat resistance, tensile strength as well as impact resistance. Dependent on the chemical composition, molecular structure plus production process of propylene polymer, there happens to be four main types of PP pipes, namely, PP-H, PP-B, PP-R and PP-RCT.

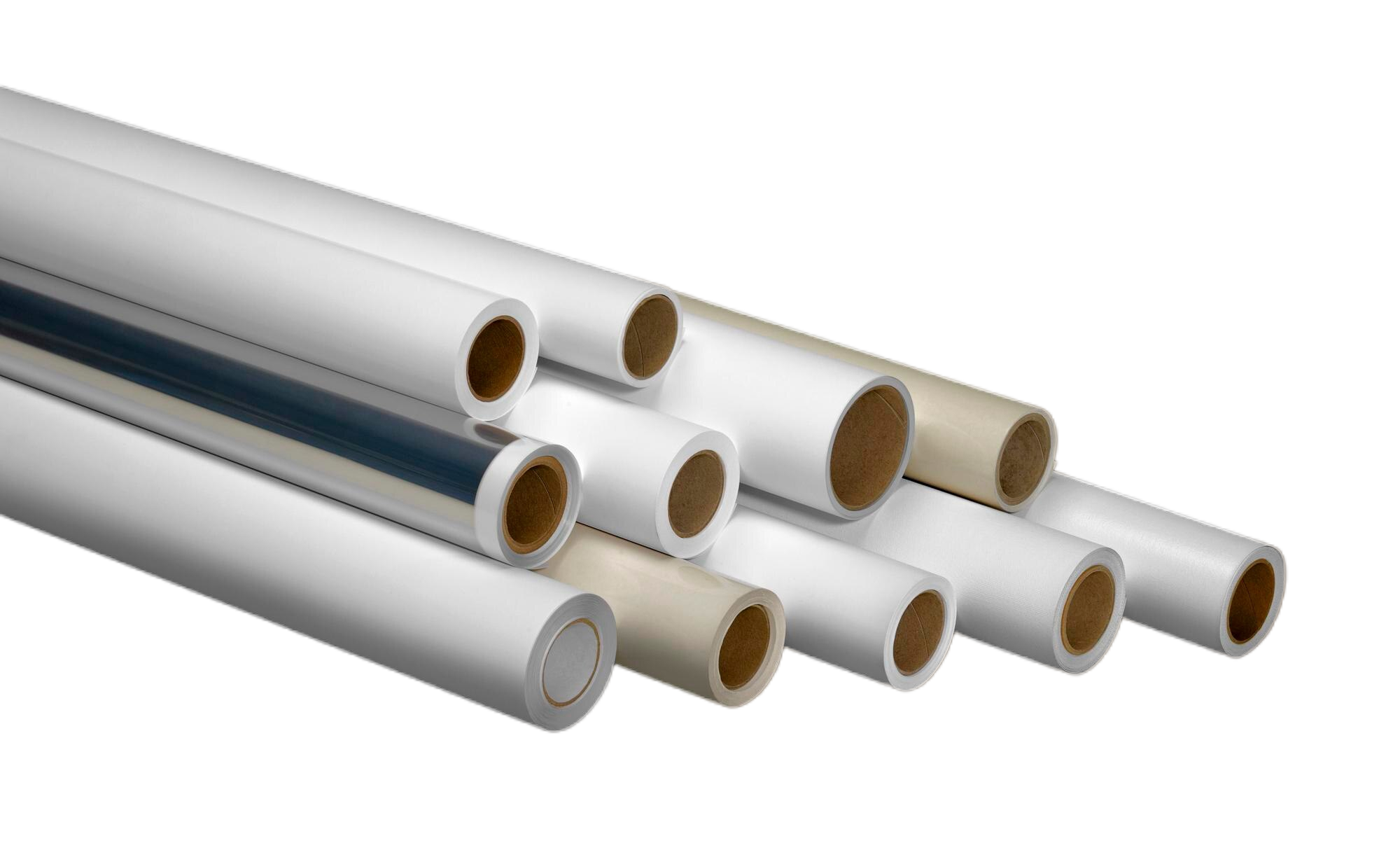

Polyproplyene-Homo (PP-H) piping system, also known as PPH piping, is a kind of plastic piping system which has gained extensive usage over the past several years. It is an indeed reliable and cost-effective substitute to traditional piping systems that are generally, made of copper, steel, or other materials.

What are PPH Pipes and fittings?

PPH (Polyproplyene-Homo) pipe is formed of high-density polypropylene (PPH) as the main body along with a considerable amount of antioxidants, anti-UV agents as well as colorants. PPH is a homopolymer polypropylene that reveals high molecular weight and low melt flow rate. It is a beta-modified ordinary PP material to give it a uniform and delicate beta crystal structure accompanied with excellent chemical corrosion resistance as well as wear resistance, high-quality products with very well high temperature resistance, good corrosion resistance, considerable aging resistance as well as insulation, making it have extraordinary impact strength even at low temperatures, adding to an increase in its hydrostatic strength and enhancing chemical resistance.

AnZ waters is the leading supplier of PPH pipes and fittings. We have acquired quite a position among the great dealers of PPH products. An experience of over 20 plus years have made AnZ Waters, efficient vendors in the wide spectrum of PPH pipes and fittings.

Characteristics of PPH Pipes and Fittings

- Chemical resistance: If we consider all the polypropylene pipes and fittings, experiments have proven that PPH pipes and fittings possess the strongest chemical resistance and can bear up against high concentrations of acids and alkalis with a pH value ranging from 1 to 14 in a broad range of corrosion.

- Long service life: PPH pipes and fittings have a longer service life and higher system safety. They can be brought into use safely for more than 50 years under rated temperature as well as pressure conditions.

- Impact strength: As compared to the traditional pipes, PPH pipes have significantly low-temperature impact strength.

- Stress resistance: PPH pipes and fittings have low notch sensitivity, high shear strength along with excellent scratch resistance. Furthermoere, their environmental stress cracking resistance is also quite outstanding.

- Temperature resistance: In accordance with actual application conditions, the applicable temperature range of PPH pipe happens to range from -20℃ to +110℃.

- Heat-resistant and energy-saving: PPH pipes and fittings have a small thermal conductivity and good thermal insulation performance.

- Pressure resistance: Out of all the polypropylene materials used in piping systems, PPH pipes and fittings have the highest pressure resistance (MRS10).

- High performance: PPH pipe’s extraordinary performance, quite flexible use of welding equipment as well as professional technical support team can not merely ensure the welding and installation quality of PPH pipe system, but as well provide customers with services as required. They also provide customized processing of non-standard products.

- Wear resistance: The wear resistance of PPH pipes and fittings comes to 4 times that of steel pipes.

- Reliable connection performance: The strength of the hot-melt joint of PPH pipes is considerably higher than that of the pipe body. In addition to this, the joints will not be disconnected due to soil movement or load.

- Good construction performance: PPH pipes are light in weight, possess simple welding process, very convenient construction, low overall project cost. Moreover, they can even meet complex process pipelines.

- Hygienic and non-toxic: This product proves to be a green building material which can be safely used in drinking water pipeline systems.

Applications of PPH pipes and fittings

1.Plumbing Systems-

PPH pipes and fittings play a vital role in plumbing systems within residential, commercial, as well as industrial buildings. They are utilized for water supply lines, drainage systems, and also wastewater management. PPH’s excellent corrosion resistance, quite good chemical inertness, coupled with durability makes it quite an ideal choice for plumbing applications. In addition to that, the ease of installation and flexibility of PPH fittings augment to not only efficient but also cost-effective plumbing systems.

2.Heating, Ventilation, and Air Conditioning (HVAC)

In HVAC systems, PPH pipes and fittings are generally used for ductwork and air distribution. The lightweight nature of PPH, coupled with its high impact strength, permit an easy installation and maintenance. PPH fittings also offer superb thermal insulation properties, reducing heat loss, as a result, ensuring optimal energy efficiency in HVAC systems. Their remarkable resistance to corrosion and chemical degradation further upgrade their suitability for HVAC applications.

3.Fire Protection Systems

PPH pipes and fittings are essential for fire protection systems in buildings. The beneficial fire resistance properties of PPH, along with its low flammability and high melting point, makes it quite a reliable material for fire sprinkler systems, fire hydrants, and fire suppression pipelines. PPH fittings can bear up against the high temperatures associated with fire incidents, ensuring the integrity of the fire protection system which in turn contributes to the safety of not only occupants but also property

4.Rainwater Harvesting Systems

Talking about sustainable building practices, rainwater harvesting systems are becoming increasingly famous. PPH pipes and fittings are commonly used in these systems for the purpose of collection, filtration, and distribution of rainwater. PPH’s excellent chemical resistance ensures that the harvested water remains uncontaminated. In addition to that, its durability ensures longevity in outdoor environments. PPH fittings contribute a great deal to sustainable water management in construction projects, that reduces reliance on municipal water supplies.

5.Industrial Applications

Throughout industrial facilities, PPH pipes and fittings fittings find a number of applications. They are employed in chemical processing plants, where they handle corrosive chemicals and bear up against high temperatures. PPH fittings also play a crucial role in industrial ventilation systems, waste treatment facilities, as well as manufacturing processes. The very beneficial combination of chemical resistance, durability, combined with ease of installation makes PPH an ideal product for demanding industrial applications like these.

AnZ waters have a wide range of PPH pipes, fittings and valves that are listed below

- PPH pipes

- PPH coupling sch

- PPH TEE

- PPH elbow

- PVPH reducer

- PPH y-strainer

- PPH male adapter

- PPH female adapter

- PPH threaded fittings

- PPH valve

- PPH ball valve

- PPH diaphragm valve

- PPH primer

- PPH glue